SkyMes AI Vision

Automated Defect Detection with Computer Vision

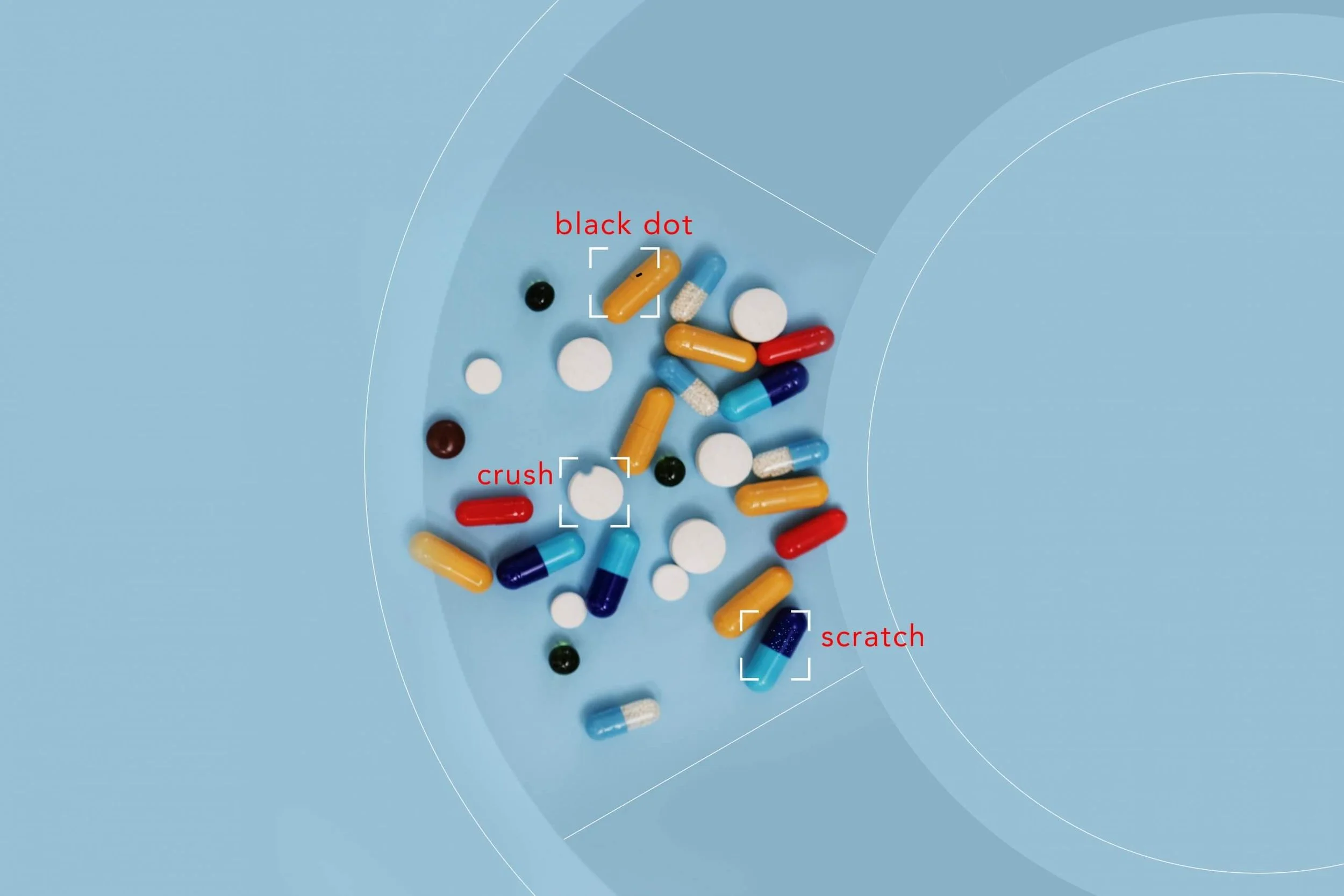

In modern factories, visual defects like scratches, spots, missing parts, deformations and foreign particles are a leading cause of cost, rework, and customer dissatisfaction.

With SkyMes’ new Computer Vision Defect & Anomaly Detection module, our QCMS suite can now automatically analyze product images, flag irregularities, and feed them into your traceability and non-conformity workflows, all in real time.

This is not just a “vision add-on”: it's deeply integrated with SkyMes’ MES, QCMS, traceability, and alerting systems. Whether during production, post-assembly, or prior to packing, this feature brings AI into your quality loop.

How it works (at a glance)

-

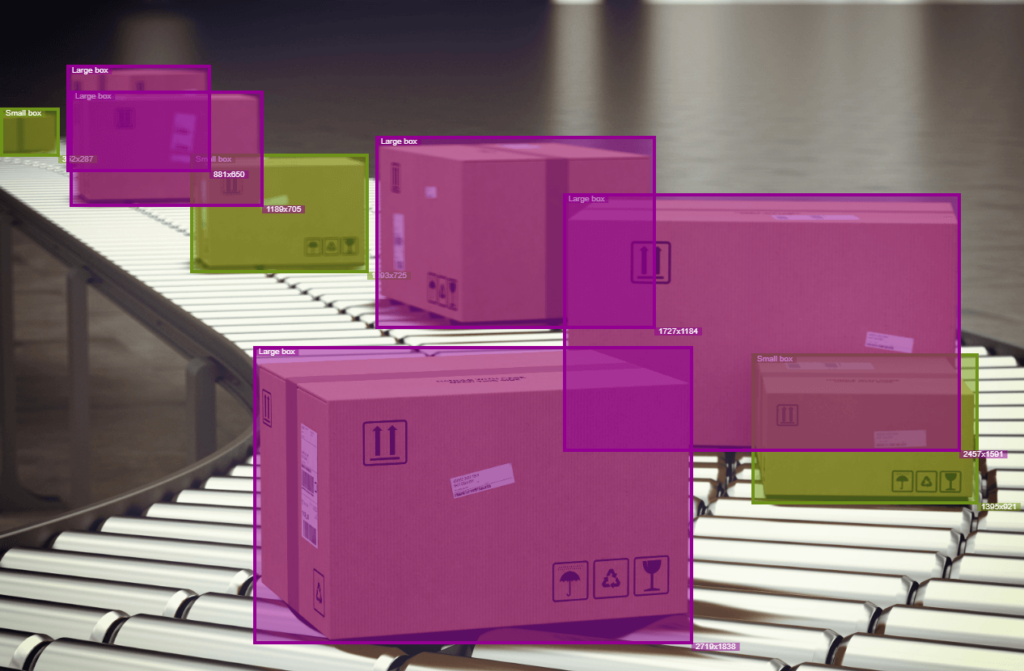

High-resolution cameras (or vision hardware) capture product images from preconfigured angles and lighting.

-

The system corrects for lighting variation, aligns, filters noise, and normalizes inputs.

-

A trained deep learning model compares each image to the “ideal” baseline and identifies deviations

-

Detected anomalies are classified (scratch, stain, crack, missing piece, etc.) and given severity or confidence scores

-

Only anomalies above configured thresholds are flagged, reducing false positives

-

Flagged items generate non-conformity records, link to traceability (serial numbers, batch), alert operators, and log data for analysis

-

User validation (accept / reject) is fed back into the system to improve detection accuracy over time

Benefits?

-

Reduce scrap & rework costs by catching defects early

-

Prevent defective items from shipping to customers

-

Free human inspectors to handle exceptions. focus human effort where it matters

-

Consistent inspection no fatigue or variability

-

Better data for quality improvement, detect recurring defect patterns, root causes

-

Seamless integration with MES & traceability workflows

-

Scalable & repeatable across product lines

-

Lower cost per inspected unit as volume scales

FAQ

-

Scratch, stain, crack, missing parts, foreign particles, surface deformation, discoloration, misalignment, custom setups are also possible

-

Yes, “good” baseline images and representative defective samples help train and tune the model. Our team assists with that.

-

Controlled lighting is important. We provide guidelines and calibration tools. In tricky cases, specialized lighting (e.g. coaxial, dark-field) or filters can help.

-

Yes, with adequate hardware, detection is near real-time. In other cases, batch mode is supported.

-

Yes, via APIs / SDKs / webhooks. The module works inside SkyMes’ integrated ecosystem.

-

User validation (accept/reject flagged defects) feeds back into retraining. Also periodic re-calibration and model versioning are supported.

-

Vision system include health monitoring, fallback inspections, and alerts when camera/lens issues occur.

-

In principle yes, but some products (very glossy, transparent, extremely fine textures) may present challenges. We’ll evaluate feasibility in your context.